AUTOMOTIVE ENGINEERING

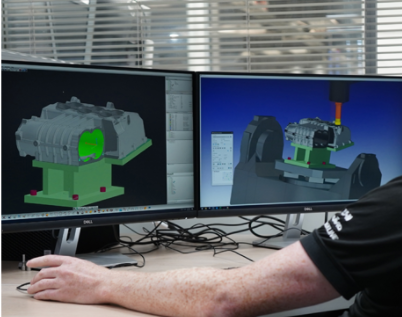

A dedicated team of qualified engineers and technicians utilize their extensive experience of modern manufacturing to deliver high-value engineering solutions to the automotive sector. Local and international training provide our skilled workforce with state-of-the-art skills in CNC software programming, modern automation equipment and global benchmarking techniques.

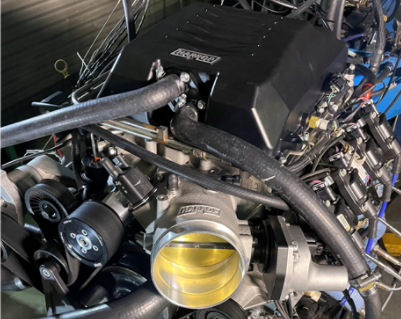

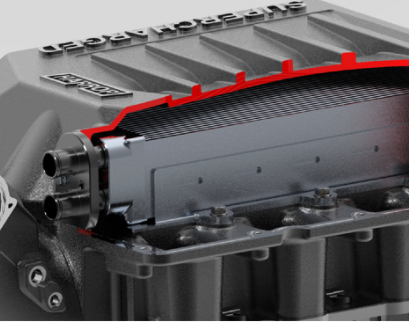

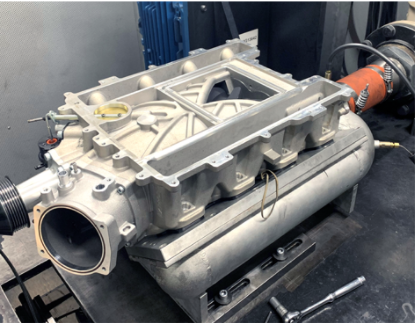

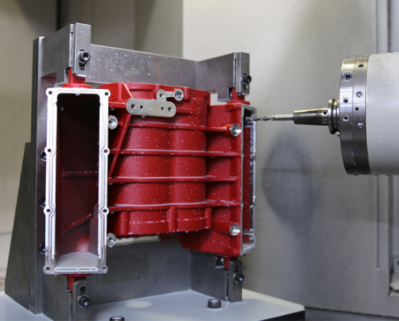

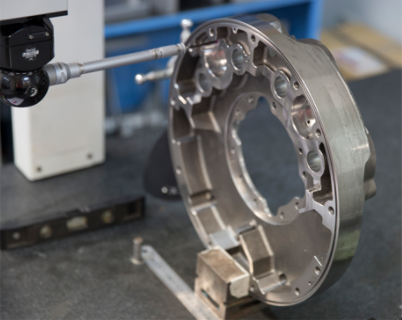

Continuous development and refinement qualify Harrop's reputation for quality products that provide real performance advantages. In-house manufacturing processes include tool and pattern design and machining, CNC finish machining of parts, assembly, verification and testing.

Harrop engineering considers every project as a complete synchronized system: conception, definition and design, project management, manufacturing, and quality control all work together to deliver results. Business partners and collaborators are worldwide, combining local ingenuity with international technology and supply.

Whether you have a conceptual idea or product already being produced, contact the team at Harrop to discuss a comprehensive quote on your Engineering requirements.

CAPABILITIES

- 3D modelling, 2D detail drawings, data translation, CNC integration

- 3D scanning & reverse engineering

- Worldwide technology partners

- Rapid prototyping

- Project management

- Aluminium casting & non-ferrous metal processing

- Precision machining, milling & turning (8 axis)

- Gear & spline cutting, broaching, profile cutting & fabrication

- Cylindrical grinding

- FEA/FMEA & design & process

- Advanced product quality planning